Mastercam creates software and services that solve the world’s manufacturing challenges.

Mastercam is a popular computer-aided design and computer-aided manufacturing (CAD/CAM) software used in the manufacturing industry. It is developed and maintained by CNC Software, Inc. Mastercam provides a wide range of tools and functionalities for creating and controlling machine tool paths to produce complex parts.

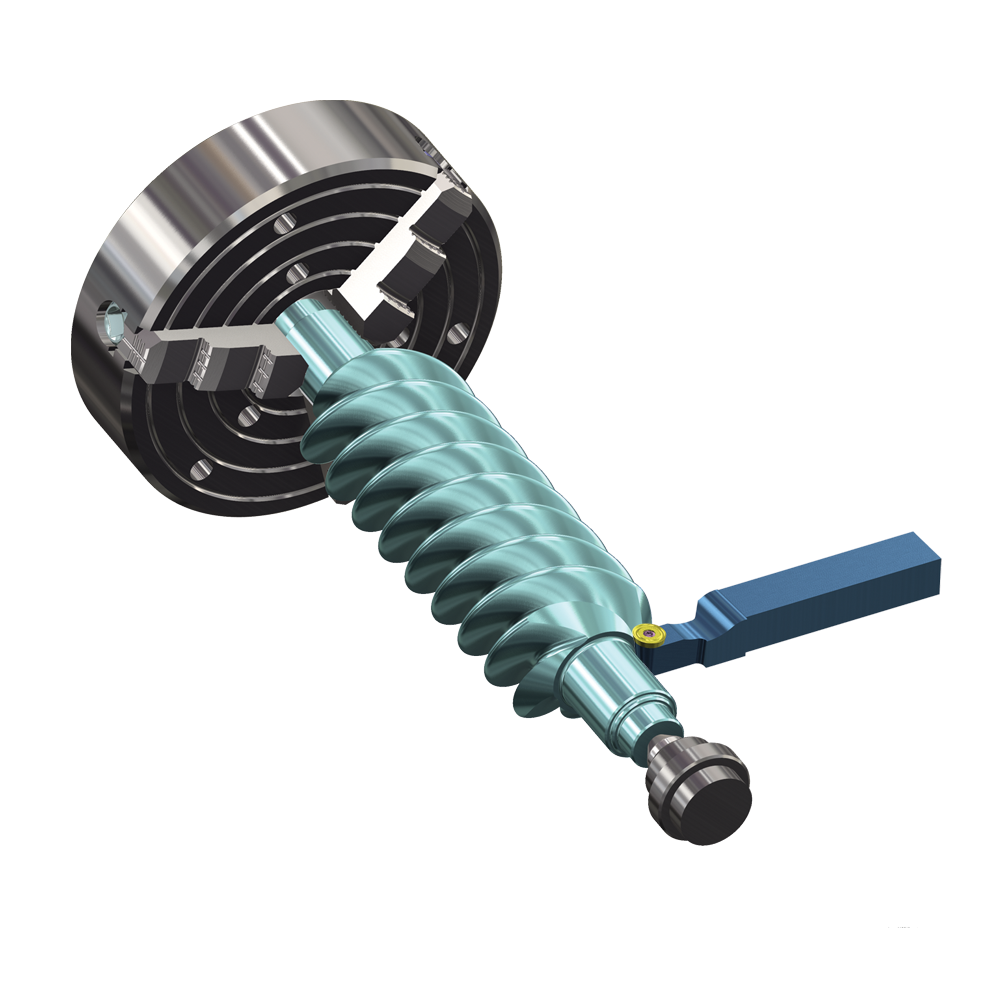

With Mastercam, users can design 2D and 3D models using a variety of CAD tools. These models can then be used to generate precise toolpaths for machining operations, such as milling, turning, routing, and wire EDM. Mastercam offers a comprehensive set of toolpath strategies and parameters to optimize machining processes and improve productivity.

Some key features of Mastercam include:

-

CAD Design: Mastercam allows users to create and modify 2D and 3D geometry, including drafting, wireframe, surface, and solid modeling tools. It supports importing and exporting various CAD file formats.

-

Toolpath Generation: The software offers a wide range of toolpath strategies, including pocketing, contouring, drilling, facing, profiling, and more. Users can define cutting parameters, tool libraries, and machining operations to generate efficient toolpaths.

-

Simulation and Verification: Mastercam provides simulation capabilities to visualize and verify the machining process before running it on the actual machine. This helps detect potential collisions, errors, or issues in the program.

-

Post-processing: Once the toolpaths are generated, Mastercam can output the NC (numerical control) code specific to the machine tool being used. The software supports a wide range of machine controllers and can be customized using post-processors.

-

Integration with CAM Tools: Mastercam integrates with various CAM tools and technologies, including tool management systems, machine simulation software, and machine monitoring solutions, to enhance productivity and streamline the manufacturing process.

Mastercam is widely used in industries such as aerospace, automotive, medical, mold and die, and general manufacturing. It is known for its user-friendly interface, extensive toolpath options, and robust support network. The software is regularly updated with new features and enhancements to keep up with industry demands.

|

|

Mastercam Lathe Solutions |

Mastercam Wire Solutions |

|

|

|

|

|

|

Mastercam Mill-Turn Solutions |

Mastercam Educational Solutions |

System Requirements

| Minimum | Recommended |

| OS |

Windows 10 or Windows 11 64-bit Professional

|

Windows 10 (version 20H2 or later) 64-bit Professional

|

|---|---|---|

| Processor |

Intel® or AMD 64-bit processor, 2.4 GHz or faster

|

Intel i7 or Xeon® E3, Kaby Lake or later, 3.2GHz or faster

|

| Memory |

8 GB

|

32 GB

|

| Video |

OpenGL 3.2 and OpenCL 1.2 support with 1 GB memory. No onboard graphics.

|

NVIDIA Quadro® or AMD FirePro™ / Radeon Pro card with 4 GB (or higher) dedicated memory.

|

| Monitor |

1920 * 1080 resolution

|

1920 * 1080 resolution, dual monitors

|

| Storage |

Solid State Drive (SSD) with at least 20 GB free and a USB 2.0 reader (for installation media)

|

NVMe Drive with at least 20GB free

|

| 3D Mouse |

|

3Dconnexion 3D mouse

|

Connection to Internet and email is recommended for installation, support, and updates.